Product design

Seamless Plastic Product Design

Our Plastic Product Design services focus on creating efficient, manufacturable solutions that ensure high-quality, cost-effective results every time.

Concept Design

Assist clients with initial product ideas, using CAD tools to visualize and iterate designs. Quick sketches of potential concepts with a focus on broad features.

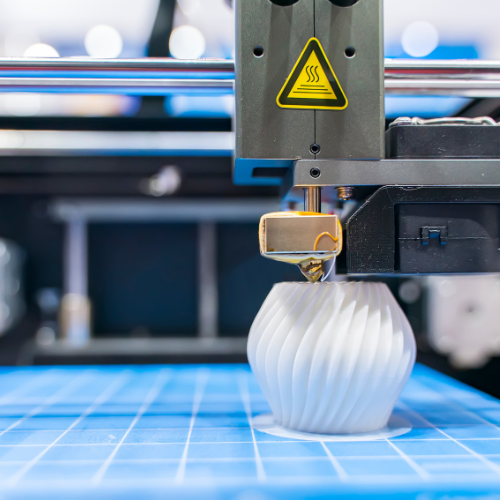

Prototyping

range of solutions to help bring your ideas to life quickly and efficiently. We specialize in plastic casting, 3D printing, and prototype rapid molds, allowing for fast turnaround times and cost-effective testing of designs

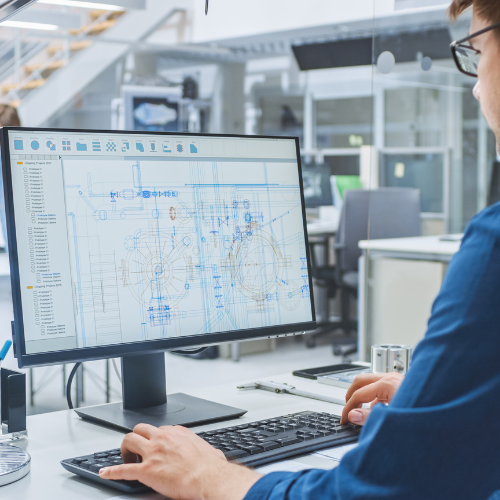

CAD engineering

We offer CAD design and engineering simulation services, including FEA analysis, to optimize product performance, enhance manufacturability, and ensure cost-effective, high-quality solutions for your projects

Assembly Design

Design products not just as individual parts, but with assembly and manufacturing in mind. This service can also include automation considerations for assembly lines to improve efficiency.

Design Service In Bookable Stages

1. Free Discovery Call

- Duration: 15 minutes

Goal: Understand your idea, see if there’s a fit, and introduce our design process.

2 – Product Design Kickoff

Deliverables:

- Review of client requirements.

- Discussion of functionality, aesthetics, and production goals.

- Preliminary sketches or concept review.

- Project plan of design concepts

3– Design Concept Presentation

Deliverables:

- CAD models of initial design concepts.

- Feedback discussion.

- Next steps or refinement direction.

- Design report.

4. Detailed CAD Modeling & Material Selection

Deliverables:

- Fully detailed 3D CAD models (SolidWorks or equivalent), optimized for moldability.

- Design for Manufacturability (DFM) report highlighting draft angles, wall thickness, undercuts, etc.

- Material selection matrix comparing biocompatibility, sterilization compatibility, and mechanical properties.

5: Prototype Development & Iteration

Deliverables:

- Functional prototypes via 3D printing or CNC (SLA, SLS, or machined plastics depending on use).

- Updated CAD models based on test findings and client feedback.

- Demo or walk-through video showing prototype in action, if applicable.

6. Design Freeze & Pre-Production Package

Deliverables:

- Final CAD and 2D drawings (with GD&T, tolerances, thread specs, and assembly notes).

- Complete Bill of Materials (BOM) with part numbers, suppliers, and material grades.

- Regulatory documentation package (ISO 13485-ready design history files, if applicable).

Why choose our design services?

With a deep understanding of materials, molding processes, and production techniques, we optimize designs for manufacturability, ensuring high-quality products that are cost-effective to produce.

- Cost Efficiency

- Risk Reduction:

- Comprehensive Support:

What You Get

When you use our design service, you receive tailored solutions that ensure optimal functionality, efficiency, and cost-effectiveness, designed to meet your specific needs.

- Detailed design-for-manufacturing reviews

- Comprehensive material selection and testing

- Rapid prototyping to speed up processes