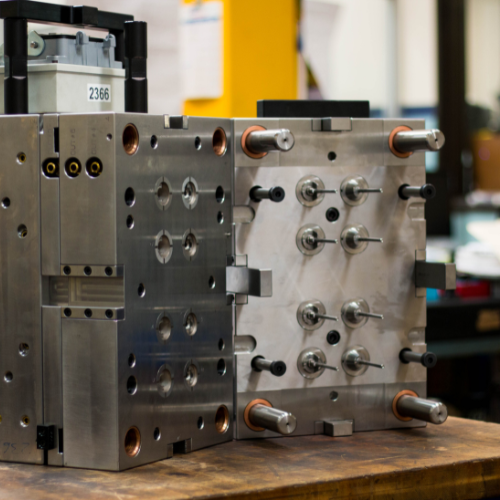

Mold making

Precision Molds, Perfect Parts.

We offer high-quality mold-making services through our trusted global partners, ensuring precision, durability, and cost efficiency. From prototype to production tooling, we deliver expertly crafted molds tailored to your exact specifications.

Custom Mold Design & Engineering

Our Tool Design & Engineering services deliver high-precision, cost-effective molds and tooling for efficient production. We ensure durability, quality, and seamless integration, optimizing performance and reducing downtime for your manufacturing needs.

High-Precision Mold Manufacturing

CNC machining, EDM, and other advanced tooling methods Tight-tolerance mold production for medical, automotive, and consumer products Multi-cavity, high-volume, and prototype tooling solutions

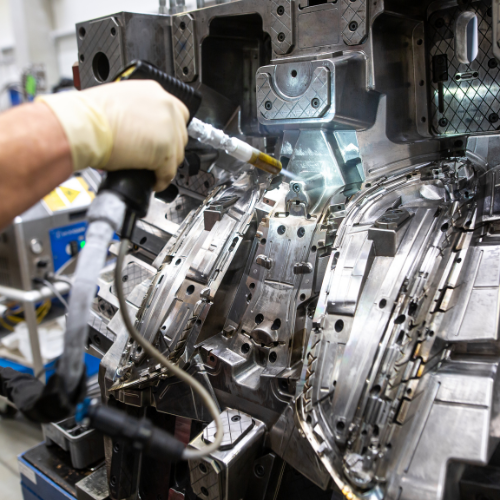

Mold Testing & Validation

In-house or partnered mold trials to ensure part quality Process validation support (IQ/OQ/PQ) for regulated industries Fine-tuning for cycle time optimization and longevity

Mold Maintenance & Support

Preventative maintenance programs to extend mold life Refurbishment, repairs, and modifications for existing molds Global support for on-site troubleshooting and process optimization

Mold making In Bookable Stages

1. Free Discovery Call

Purpose: Understand the product, volume requirements, timelines, and special tooling considerations.

Fee: Free

- Initial project intake and needs assessment

- Tooling feasibility discussion (materials, part complexity, volumes)

- Discussion of offshore vs. local tooling pros & cons

- Follow-up summary with proposed next steps

2. Mold DFM & Tooling Strategy Planning

Purpose: Review part design for tooling and define the mold specification strategy.

- Design for Moldability (DFM) report covering gates, draft, wall thickness, undercuts, etc.

- Tooling requirement document (steel type, cavities, mold class, cooling system, etc.)

- Tooling RFQ package sent to the appropriate tool makers.

- Tooling costs review meeting summary with agreed next steps

3. Mold Design Oversight

Purpose: Manage the tool design process with selected tooling partner.

- Mold flow simulation report (if applicable) for material flow and shrinkage prediction

- 2D & 3D mold design review files (core/cavity layout, ejector system, gating, cooling channels)

- Consolidated design feedback and change request list

- Client approval form for final tool design

4. Tool Build Management

Purpose: Oversee the actual tool manufacturing and ensure timely progress.

- A tool schedule with key milestones and deadlines

- Weekly photo/video progress updates from the toolmaker

- Inspection report of mold components (steels, inserts, moving parts) before assembly

- Regular toolmaker-client communication updates (managed by our team)

5. Mold Trials & Validation

Purpose: Ensure the mold produces quality parts as designed and perform necessary tuning.

- Trial shot samples (T0/T1) shipped to client for review.

- Trial run report including full process development report.

- Tuning and modification plan (if applicable, based on T1 results).

- Mold trial video walkthrough with commentary on any observations.

6. Mold Approval & Handover

Purpose: Final acceptance and delivery of the tool for production.

- Final part approval report including any outstanding design notes.

- Tooling documentation pack (assembly drawings, 2D prints, BOM, recommended maintenance).

- Shipping and customs coordination summary (with tracking info).

- Client handoff session covering maintenance, storage, and next production steps

Why choose our mold making service

Choose our mold-making service for precision-engineered, high-quality molds tailored to your needs. We offer expert design, fast turnaround, and cost-effective solutions to ensure optimal performance and durability.

- Precision-engineered molds for high-quality parts.

- Fast turnaround with expert craftsmanship.

- Cost-effective solutions tailored to your needs.

What You Get

Get high-precision molds with expert DFM, robust validation, and optimized cycle times. We ensure superior quality, tight tolerances, and efficient production for your plastic parts. Reliable, cost-effective, and built to last.

- Expert Molding advice for Optimize design.

- Navigate supplier challenges, tooling, and process validation.

- Reduce cycle times, enhance quality, and ensure compliance.